PPE Info

On this page we have various information regarding standards and requirements for Hi Vis specs, hearing protection, safety eyewear , cut resistant gloves and safety footwear.

Hi Vis EN ISO 20471 Safety Specifications

Please bear in mind that all eniso20471 and RISTOM3279 specifications relate to items that are unblemished and no logos. There is only so much logo space that can be added to these items before the item becomes non compliant with EN regs please ask us if having more logos than 230mm wide to rear and 100mm wide to front as this may invalidate the product. See below.

Hi Vis En iso20471 standard is en iso 20471 2013:. This means all hi vis clothing being manufactured after this date must comply to the new regulations. **note from 1st June 2013 a newer set of testing standard came in to force called EN20471 and the major changes are outlined below our en iso 20471 regs .The regs are defined by various testing organisations such as the BSI and other authority testing bodies. This ensures that the Hi Vis Vests and clothing you are wearing are up to the required safety standard as long as the diplay the en iso 20471 2033 standard mark.

There is also a seperate hi vis spec dedicated to the rail industry for GORT vests and jackets, usually orange hi vis. This also incorporates the pull apart hi vis vests spec, en510 for people wearing Orange Rail hi vis when working on or near railways where moving trains or equipment is to be used.

Only YELLOW and Orange hi vis vests are full en iso 20471 spec by legislation.

Red vests, green vests and all other colours do not meet en iso 20471 specification

Below are some of the required codes and safety explainations for various items of Hi Visibility and Personal Protective Equipment.

![]() High Visbility

High Visbility

en iso 20471 - Specification for High Visibility Clothing

en iso 20471: 1994 has been replaced by en iso 20471:2003>

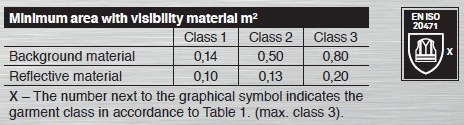

There are 3 classes of hi vis garments based on the provided levels of visibility. On these hi vis garments the hi vis reflective tape must not be any less than 50mm wide.

|

CLASS 3 THE HIGHEST LEVEL OF CONSPICUITY Minimum background material 0.80m2 Minimum retro-reflective material 0.20m2 |

|

CLASS 2 INTERMEDIATE PROTECTION Minimum background material 0.50m2 Minimum retro-reflective material 0.13m2 |

|

CLASS 1 LOW LEVEL PROTECTION Minimum background material 0.14m2 Minimum retro-reflective material 0.10m2 |

Selection of the most suitable class of garment is based on your risk assessment. However, in certain situations guidance is given, such as if you are working on the highways the 'Safety at Street Works and Road works' and the 'Traffic Signs Manual Chapter 8' provide information on what type and class of protective clothing you should be wearing.

EN20471 new regs from 1st June 2013.

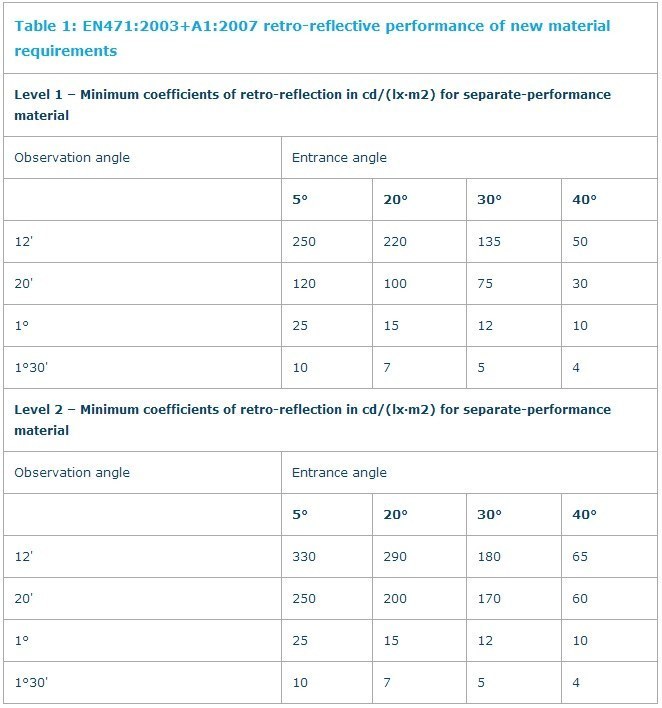

1. Retro-reflective tape - Class 1 retro-reflective tape is no longer an option, ISO 20471 requirements for single performance retro reflective tape is identical to the en iso 20471 Class 2 tape. However the for performance after washing the test method differs as 20471 requires each cycle to be a wash and dry cycle whereas 471 only required washing after the last cycle. (Product markings no longer will state the performance class of the retro reflective tape). Combined performance tape may still be used on class 1 garments. (again, the test method has changed).

2. Placement of retro-reflective tape - the mandatory patterns for retro-reflective tape remain unchanged, except now it I clarified that additional bands of tape may be used to achieve the required areas.

3. Class 3 garments must now be garments which cover the torso and have either full length sleeves and or full length legs.

4. Garments with short sleeves if the sleeve obscures a torso band of retro reflective tape must now have a band of retro-reflective tape about the sleeves also.

5. If the maximum number of washes (or Dryclean cycles) is stated by the manufacturer then fluorescent background material must meet the chromaticity and luminance requirements after the specified number of washes. If no maximum number of washes is stated then it must meet after 5 washes and this must be reflected in the user information.

6. Tensile strength requirement on fabrics has been reduced

7. Burst strength requirement on fabrics has been reduced

8. Tear strength requirement on coated fabrics/laminates has been reduced

9. Colourfastness to perspiration has had the staining requirement increased to 4

10. Colourfastness to washing/drycleaning has had the staining requirement reduced to 4 for non-fluorescent fabrics.

11. Water vapourpermeability requirements for fabrics (Excluding Coated/laminate fabrics for protection against rain(not required for vests/waistcoats) requirement has been amended to <5 m2Pa/W or water vapour permeability index <=0.15

The title of the new standard “High visibility clothing - Test methods and requirements” removes the previous distinction between professional and non- professional use and the new standard is concerned with risk assessment and risk analysis for the selection of the correct visibility clothing for high risk scenarios. Annex A (informative) defines the various factors that need to be taken into account when conducting such an analysis.

The standard specifies the requirements for high visibility clothing “which is capable of visually signaling the user’s presence”. The new standard has broadened the usage base and a distinction between different types of risk situations has been made. The defined risk situations will be the basis for which norm is applicable for the user. ISO EN 20471 isapplicabletohigh-risksituations.

Class 3: Highest Level

Highest level of protection - required for any persons working on or near motorways or dual-carriage ways or airports. Must incorporate a minimum of 0.80m2 of background material and 0.20m2 of retro-reflective materials. (4 metres of 5cm wide reflective tape).

Class 2: Intermediate Level

Required for any persons working on or near A and B class roads, also for delivery drivers. Must incorporate a minimum of 0.50m2 of background material and 0.13m2 of retroreflective material. (2.60 metres of 5cm wide reflective tape).

Class 1: Minimum Level

Minimum level of protection required for any persons working on a private road or to be used in conjunction with a higher classed garment. Must incorporate a minimum of 0.14m2 of background material and 0.10m2 of retroreflective material. (2 metres of 5cm wide reflective tape).

In the new norm, all class 3 garments must cover the torso and have as a minimum either sleeves with retro reflective bands or full length trouser legs with retro reflective bands.

This ends the possibility to CE mark sleeveless class 3 garments. If a short sleeve is covering a torso band, retroreflective tape must be fitted on the sleeve.

It is now also possible to CE mark separate garments together (instead of a single garment) to fulfill a requirement for a certain performance class. This is achieved by a so called clothing ensemble: e.g. by certifying jackets and trousers together.

The possibility to CE mark harnesses has been removed in the new standard.

Garment Design/Ensemble

The design requirements set out in the standard EN ISO 20471:2013 maintains a three-class system for garments, which is based on minimum areas of visible high-visibility materials present in a garment, whereby class 3 garments provide the highest level of conspicuity.

The standard also permits this performance class to be met by specifying a single garment or an ensemble – for instance, a class 2 jacket and a class 2 pair of trousers might be combined and certified as a class 3 ensemble. Where an ensemble is specified, this will be deemed to meet the requirements of the standard only when the supplier provides clear instructions on how the classification has been achieved.

A class 3 garment is required to cover the torso and have sleeves with reflective bands or/and trouser legs with reflective bands.

The area of background or retroreflective material that is covered by badges logos, lettering etc shall be excluded from the calculation of the required minimum area (unless these additions meet the requirements).

Garments covering legs – for instance, waistband and bib and brace trousers, and shorts

Bib & Brace trousers can no longer meet Class 3 as they do not cover the torso. They no longer need to have a torso band.

Garments covering torso and legs – including coveralls without sleeves

Garments covering torso, arms and legs – for example, coveralls with sleeves.

Clothes in class 1 or 2 can be combined to obtain class 3.

It will be specified on the CE-label in your high visibility garment. Check the labels to safely choose the right class and combination for the proper protection your work requires.

The symbol indicates that the garment is certified and approves to EN ISO 20471. The number next to the symbol shows the class. All reflective tape are in the highest category referred to as category 2 in en iso 20471.

The new standard requires that high visibility garments are tested after washing.

This will increase your safety, and ensures the same protection after, as well as pre wash.

All three high visibility colours: yellow, orange and red, pass the high demands of the EN ISO 20471 standard. The contrast colour can be any colour as long as it passes the EN ISO 20471 test and is not bleeding or decreases the protection of the fabric after wash.EN 1150

GO/RT 3279 Clothing

The GO/RT 3279 standard is based on the European standard en iso 20471:2003 + A1:2007. It requires garments to meet at least class 2 (the mid-point of a 3-class scale) of en iso 20471 for the minimum area of high-visibility materials used within a garment. Whereas the European standard permits several different colours of high-visibility materials, the railway standard specifies an orange colour.

Railway locomotive headlights pick out retro-reflective materials in high-visibility clothing. Again, the railway standard draws on en iso 20471:2003 + A1:2007 and specifies materials for use that meet the highest level of photometric performance criteria that are specified within the standard.

GO/RT 3279 also defines the requirements for a high-visibility minivest. These are required to conform to class 1 design requirements of en iso 20471:2003 + A1:2007, except they need to exceed the requirements in en iso 20471 for both the minimum area of the orange background material and retro-reflective tape used in the garment.

This is the standard non-professional use for example, jogging, cycling or other traffic related interaction activities. This would include sports users who need high visibility for cycling, road running, driving etc.

Whilst en iso 20471 specifies a set of requirements for high visibility warning garments for professional use in the work place, the EN 1150 standard provides details for non-professional use, together with criteria for minimum area’s and placement of reflective material to achieve enhanced conspicuity. Garments conforming to these standards are capable of signalling the users presence visually, under any light conditions, both by day and under illumination by vehicle headlights in the dark.-

EN1150 is being replaced with En17353:2020 . Due to brexit, imports are taking longer to filter through so the date has been pushed back to sept 2022 and is still under review. During this time all en1150 garmets are suitable until phased out.

The standard specifies requirements for enhanced visibility equipment in the form of garments, or devices, which are capable of signalling the user’s presence. The enhanced visibility equipment is intended to provide more conspicuous visibility of the wearer in medium risk situations under any daylight conditions and/or under illumination by vehicles headlights or searchlights in the dark.

EN 17353:2020 – Protective clothing – Enhanced visibility equipment for medium risk situations – Test methods and requirements, supersedes two separate standards and brings together elements of each of the withdrawn standards:

- EN 1150:1999 – Protective clothing – Visibility clothing for non-professional use – Test methods and requirements

- EN 13356:2001 – Visibility accessories for non-professional use – Test methods and requirements

All products meeting the requirements of the standard are no longer considered in terms of their use, but rather their suitability in providing protection in medium risk situations as defined by their enhanced visibility properties.

The EN 17353 standard is applicable to clothing and devices worn in medium risk situations such as working with slow-moving vehicles, jogging on roads with lower traffic speeds, or cycling. It sets forth the minimum amounts of materials that should be incorporated into products in order to ensure enhanced visibility on an end user. The standard also describes the design requirements for various types of products based on the foreseeable conditions of use by Type “A”, “B” and “AB”.

Type A– Equipment worn by users where the risk of not being seen exists only at daylight conditions. This equipment uses only the fluorescent material as an enhanced visibility component.

Type B – Equipment worn by users where risk of not being seen exists only at dark conditions. This equipment uses only the retroreflective material as an enhanced visibility component. Including:

- Type B1 – free hanging retroreflective devices

- Type B2 – retroreflective devices temporarily or permanently placed on limbs only

- Type B3 – retroreflective material placed on torso or torso and limbs

Type AB – Equipment worn by users where risk of not being seen exists during daylight, twilight and dark conditions. This equipment uses the fluorescent as well as the retroreflective and/or combined performance materials as enhanced visibility components.

However, the EN 17353 standard is not applicable to:

- High visibility equipment in high-risk situations, which is covered in EN ISO 20471;

- Visibility equipment specifically intended for the head, hands, and feet, e.g. helmets, gloves and shoes;

- Equipment integrating active lighting, e.g. LEDs;

- Visibility for low-risk situations.

All products subjected to EN 17353:2020 are considered as Category II Personal Protective Equipment according to (EU) 2016/425 and requires an EU Notified body to undergo a CE compliance assessment procedure in order to be marketed with the CE mark when used in the eu, or the UKCA mark in the UK after brexit.

![]() Protection Against Foul Weather

Protection Against Foul Weather

EN343:2003

Performance criteria governs the resistance to water penetration and water vapour resistance (breathability) of the garment.

![]() Protection Against Heat And Flame

Protection Against Heat And Flame

Note: This product has specification EN533. A fuller explanation of the standards in this area are shown below.

EN533 (EN 533:1997 has been replaced by EN ISO 14116:2008 “Protective clothing.) Protection against heat

and flame. Limited flame spread materials, material assemblies and clothing”.

All three standards have been listed as a Harmonised Standard in the EU Official Journal list of

harmonised PPE standards (5th June 2009).

Limited flame spread properties (being superseded by BSEN ISO 14116).

EN531 (EN 531:1995 is being replaced by EN ISO 11612:2008 “Protective clothing. Clothing to protect against

heat and flame”.)

Protective clothing for workers exposed to heat.

EN14116

EN ISO 14116: Protective clothing against limited flame spread materials

Supersedes EN 533:1997

This international standard specifies the performance requirements for the limited flame spread properties of

materials and protective clothing.

The standard is not applicable for fire fighters (EN 469) and welders (EN 470 – EN ISO 11611).

The aim is to reduce the possibility of the clothing buring and thereby itself constituting a hazard: the

wearer should not get extra injuries due to the burning of his clothing.

The protective clothing is intended to protect workers against occasional brief contact with small flames. The

working circumstances offer no significant heat hazard and there is no presence of another type of heat. For

protection against heat hazards, we gladly refer to ISO 11612 (Clothing to protect against heat and flame).

The following parameters are used:

1. Requirements for limited flame spread index 1

The flame does not spread, there are no flaming debris, no afterglow, a hole may be formed.

2. Requirements for limited flame spread index 2

The flame does not spread, there are no flaming debris, no afterglow, no hole formation.

3. Requirements for limited flame spread index 3

The flame does not spread, there are no flaming debris, no afterglow, no hole formation, the afterflame times of each individual specimen

EN470-1 (EN 470-1:1995 is being replaced by EN ISO 11611:2007 “Protective clothing for use in welding and

allied processes”.)

Protective clothing for use in welding and allied processes (being superseded by BS EN 11611:2007).

Different performance criteria for each of these standards have relevance to both fabrics and garments separately to help determine the suitability of garment. ENV50354, CLC/TS 50354, IEC 61482-1, IEC 61482-1-2 These are all standards which have been used or are being used in the constantly evolving field of protection against electric arc.

![]() Electrostatic Performance (Anti-static)

Electrostatic Performance (Anti-static)

Note: This product has specification prEN1149-5:2006. A fuller explanation of the standards in this area are shown below.

prEN1149-5:2006

Protective clothing with electrostatic properties. The series of ŒAntistatic Standards¹, 1149 have been updated and the parts are separated into test methods and performance requirements.

![]() Chemical Protection - Reduced Spray

Chemical Protection - Reduced Spray

Note: This product has specification EN13034 Type 6. A fuller explanation of the standards in this area are shown below.

EN13034 Type 6

EN13034:2005 Type 6 (PB) Partial body.

EN1513 Limited use protection for parts of the body.

EN 470-1:1995 has been replaced by EN ISO 11611:2007 “Protective clothing for use in welding and

allied processes”.

EN 531:1995 is being replaced by EN ISO 11612:2008 “Protective clothing. Clothing to protect against

heat and flame”.

EN 533:1997 has been replaced by EN ISO 14116:2008 “Protective clothing. Protection against heat

and flame. Limited flame spread materials, material assemblies and clothing”.

All three standards have been listed as a Harmonised Standard in the EU Official Journal list of

harmonised PPE standards (5th June 2009).

· EN ISO 11611: Fabric meets EN 470 Tear Strength or EN ISO 11611 Tear Strength is = 15 N

· EN ISO 11612: EN ISO 11612 Tear Strength is = 7.5 N

If Labels and User Information list the standard number they must also list the Clause Exclusions.

SAFETY FOOTWEAR SPECIFICATION

|

EN345 |

|

|

S1 |

Antistatic plus energy absorption of heel area |

|

S2 |

Antistatic plus energy absorption of heel area plus water resistant |

|

S3 |

Antistatic plus energy absorption of heel area, water resistant plus penetration resistant |

|

S5 |

200 Joule Toecap protection. Allrubber or all polymeric footwear with antistatic properties. Energy absorption of seat region. Plus penetration resistance. Cleated |

|

EN346 |

|

|

P1 |

Antistatic plus energy absorption heel |

|

P2 |

Antistatic, energy absorption heel plus water resistant |

|

P3 |

Antistatic, energy absorption heel, water resistant plus penetration resistant |

|

EN347 |

|

|

O1 |

Antistatic plus energy absorption heel |

|

O2 |

Antistatic, energy absorption heel, plus water resistant |

|

O3 |

Antistatic, energy absorption heel, water resistant plus penetration resistant |

SAFETY CLOTHING SPECIFICATION

|

EN 340 |

1993 General Requirements Protective clothing |

|

EN 348 |

Test method determination of behaviour of materials on impact of small splashes of molten metal on protective clothing |

|

EN 367 |

Protective Clothing ? protection against heat and fire |

|

EN 368 |

Protective Clothing ? protection against liquid chemicals penetration |

|

EN 369 |

Protective Clothing ? protection against liquid chemicals permeation |

|

EN 373 |

Protective Clothing ? assessment of resistance of materials to molten metal splash |

|

EN465 |

Protective Clothing- protection against liquid chemicals |

|

EN469 |

Protective clothing for fire fighters |

|

EN470 |

Protective clothing for use in welding and allied trades |

|

en iso 20471 |

High Visibility warning clothing Further detailed info on en iso 20471 can be found here |

|

EN510 |

Specification for protective clothing for use where there is a risk of entanglement with moving parts |

|

EN531 |

Protective clothing for industrial workers exposed to heat. |

|

EN943 |

Protective clothing against liquid and gaseous chemicals including liquid aerosols and solid particles |

|

EN1073 |

Protective clothing against radioactive contamination. |

|

EN1149 |

Protective clothing ? electrostatic properties

|

SAFETY EYEWEAR

EN166

Personal eye protection

Eye-protection equipment is marked with a series of numbers and/or symbols according to the field of use, the protection capabilities and performance characteristics of the eye-protector.( Note : where the ocular and the frame form a single unit, e.g. cover-spectacles, goggles, all markings are on the frame. The marking relative to oculars precedes the marking relative to the frame and the markings are separated by a hyphen.In this case the manufacturers identification mark is not repeated in the marking.)

Example of Marking

Ocular marking: 3-1.2 [S] 1 F

Frame marking: [S] EN 66-F

Mechanical Risk

|

3 Code Number |

|

|

2 |

UV filter where colour recognition may be affected. See EN170 |

|

3 |

UV filter with good colour recognition. See EN170 |

|

4 |

IR filter. See EN171 |

|

5 |

Sunglare filter ( without infra red specification). See EN172 |

|

6 |

Sunglare filter ( with infra red specification). See EN172 |

|

Note: |

|

|

1.2 Shade Number (1.2, 1.4 etc?16) |

|

|

Guidance is given in European standard EN169,170,171,172. |

|

|

[S] |

Manufacturers dentification mark |

|

1 |

Optical class ? 1,2 or 3. |

|

F, -F |

Mechanical strength |

|

S |

Increased robustness |

|

F,-F |

Low energy impact of high speed particles |

|

B,-B |

Medium energy impact of high speed particles, (goggles or face shields only) |

|

A,-A |

High energy impact of high speed particles, (face shields only) |

|

Other markings which may appear on oculars and/or frames |

|

|

K |

Resistance to surface damage by fine particles. |

|

N |

Resistance to logging |

|

4 |

Liquids. For liquid droplets use goggles only, for liquid splashes use face shields only. |

|

5 |

Large dust particles, (>5 microns). Goggles only |

|

6 |

Gasses, vapours, sprays, smoke and fine dust particles (<5 microns) Goggles only |

|

7 |

Short circuit electric arc. Face shields only. |

|

8 |

Splashes of molten metals and preparation of hot solids. Goggles or face shields only. |

HEARING PROTECTION

|

EN 352 |

|

|

1 |

Ear muffs |

|

2 |

Ear plugs |

|

3 |

Ear muffs attached to an industrial safety helmet |

|

4 |

Level dependent ear muffs |

|

5 |

Active noise reduction ear muffs |

|

6 |

Ear muffs with electrical audio input |

|

7 |

Level dependent ear plugs |

SAFETY GLOVES

Changes have been made in EN388:2016 for safety gloves. However, much remains the same. Testing of resistance to abrasion, tear and puncture are carried out as before but with some clarifications regarding test procedure and test materials. For example it is now mandatory to use a specified sandpaper during abrasion test.

Gloves that earlier been tested with less harsh sandpaper can experience lower abrasion result when testing according to EN 388:2016. The obtained test results corresponds to different levels of protection in the same way as in the 2003 version, which for resistance to abrasion, tear and puncture is 0–4, with 4 being the highest performance level.

The major differences in the new edition compared to the previous is related to cut resistance and impact protection. There are now two methods available for testing the cut resistance and the standard clearly states that there is no correlation between the old and new cut test methods. For details, see the details here

|

EN374 ? 2 |

Protective gloves against chemicals and micro organisms, determination of resistance to penetration |

|

EN374 ? 3 |

Protective gloves against chemicals and micro organisms, determination of resistance to permeation by chemicals. |

|

EN388 |

1994 Protective Gloves against mechanical risks |

|

EN407 |

Protective gloves against thermal risks (heat and/or fire) |

|

EN421 |

Protective gloves against ionising radiation and radioactive contamination. |

|

EN511 |

Protective gloves against cold |

|

EN659 |

Protective gloves for fire fighters |

|

EN12477 |

Protective gloves for welders |

Safety Helmets and head protection

Click here for general advice on safety helmet use and storage, shelf life etc.

|

EN397 |

1995: Industrial safety helmets |

|

EN443 |

1997: Helmets for fire fighters |

|

EN812 |

Industrial bump caps |

What colour safety helmet should you wear on site ?

Build UK have devised a safety helmet colour code that some sites make use of which is.

White helmet for Site Managers, Competent Operatives, or Vehicle Marshals

Orange helmet for slinger or signaller

Black helmet for Supervisors

Blue helmet for all other site workers

It is important to realise that this isn't a legal requirement, though more and more sites are adopting this colour code for safety helmets use on sites.

Selection & ANSI Z89.1-1997

The latest standards for protective Hard Hats are contained in ANSI Personal Protection -- Protective Headwear for Industrial Workers - Requirements ANSI Z89.1-1997.

Safety headwear (e.g. hard hats) shall be worn by persons in any area in which there is a potential hazard to the head from falling, flying or thrown objects, or from other harmful contacts (e.g. electrical). The standard provides minimum performance requirements 1) to reduce the forces of impact and penetration from falling objects and 2) where applicable, to provide protection from electrical shock hazards. A flammability test is also administered.

The standard provides requirements for two "Types" and three "Classes" of headwear. Each Type and Class of head protector is intended to provide protection against specific hazardous conditions. An understanding of these conditions will help in selecting the right Hard Hat for the particular situation.

Types & Classes

TYPE I - The typical hard hat - provides top of head protection from impact and penetration.

- TYPE II - Helmets provide some degree of top of head and off-center protection.

- CLASS E (Formerly Class B): Electrical (utility service, non-conducting) intended to protect against falling objects plus reduce the danger of exposure to high voltage electrical shocks and burns. Class E Hard Hats are tested for force transmission first, then tested at 20,000 volts for 3 minutes, with 9 milliamps maximum current leakage; then tested at 30,000 volts, with no burn through permitted. This Class is used extensively by employees engaged in electrical work.

- CLASS G (Formerly Class A.): General Use (limited voltage - non-conducting) intended to protect against falling objects plus reduce the danger of exposure to low voltage electrical conductors. Class G Hard Hats are tested at 2,200 volts for 1 minute, with 3 milliamps maximum leakage. This Class is widely used in mining, construction, shipbuilding, tunneling, lumbering, and manufacturing. CLASS C (No Class Change): Special service (no voltage protection) hard hats are designed for lightweight comfort and impact protection and not intended to provide protection from electrical conductors. Class C Hard Hats are not tested for electrical resistance.

- Class C Hard Hats are used in certain construction and manufacturing occupations, oil fields, refineries, and chemical plants where there is no danger from electrical hazards or corrosion and on occasion where there is a possibility of bumping the head against a fixed object.

Flammability Testing is performed on hard hats to confirm protection of 1550*F flame impingement for 5 seconds and to ensure there is no visible flame on hard hat after 5 seconds of flame removal.

Inspection & Maintenance for Hard Hats

Outer Shell - DO's & DON'TS

DO:

- Inspect headwear before each use for any visible signs of dents, cracks, gouges, penetration, chalking, loss of gloss or any other signs of damage prior to use that might reduce the degree of safety originally provided. Users are cautioned that if unusual conditions occur, such as extreme high or low temperatures or if there are signs of abuse or mutilation of the hard hat or any component, the margin of safety may be reduced. Where damage or defects are detected, the Hard Hat should be discarded and replaced with a new unit.

- Replace Hard Hat even when hairline cracks start to appear.

- Replace Hard Hat that has been struck by a forceful object, even if no damage is obvious.

- Remove and destroy any hard hat if its protective abilities are in doubt.

Note: Safety headwear will deteriorate over time from exposure to sunlight and other chemicals. The normal service life of a hard hat is considered to be 5 years from the date of manufacture which can be found permanently marked on the inside surface of the hard hat shell.

DO NOT:

- Do not drill holes, alter or modify the shell. Alterations may reduce the protection provided by the hard hat.

- Do not use paint, solvents, gasoline, chemicals, or harsh cleaning materials on the shell. These can make plastic headwear brittle, more susceptible to cracks and reduce protection by physically weakening it or negating electrical resistance. Paint can also hide cracks that may develop. Instead, use OccuLux or OccuLux II Reflective and Regular logos to customize or reinforce your graphics.

- Do not use winter liners that contain metal or electrically conductive material under Class G or E Vulcan Hard Hats.

- Do not use metal labels on Class G or E Hard Hats.

- Do not transport headwear in rear windows of vehicles since sunlight and extreme heat may adversely affect the degree of protection.

- Do not draw the chin strap over the brim or peak of the Hard Hat.

- Do not wear Hard Hat backwards. The peak should always face forward. .

The Suspension - DO's & DON'TS

DO:

- Inspect suspension before every use. It's life span is affected by normal use, heat, chemicals and ultraviolet rays. Where damage or defects are detected, the suspension should be discarded and replaced with a new unit. Hard Hat Suspensions will deteriorate over time from exposure to sunlight and other chemicals. The normal service life of the Suspension is considered to be 1 year of regular use. Where use is intermittent, the suspension may last longer.

- Look closely for cracked, torn or frayed suspension material or adjustment slots.

- Check the suspension lugs carefully. Long periods of normal use can damage the Suspension. Perspiration and hair oils can speed up the deterioration of Suspension materials.

- Replace the Suspension if it has torn or broken threads.

- Adjust headband size so that headwear will stay on when the wearer is bending over, but not so tight that it leaves a mark on the forehead.

- Ensure that the Suspension is in good condition. The main purpose of the Suspension is to absorb energy.

DO NOT:

Do not put anything between the Suspension and the shell. There must be clearance inside the headwear while it is being worn. In case of a blow to the head, that space helps absorb the shock.

Do not mix different manufacturer Suspension types and hard hats. Replacement suspension harnesses shall be from the same manufacturer and for the same model of hard hat. Cleaning Clean Vulcan Hard Hat shell and suspension regularly according to the OccuNomix instructions. Immerse in hot water (Approximately 140*Fahrenheit/60* Celsius) with mild anti-bacterial detergent for one minute. Scrub and rinse in clear hot water.

What Are Employer's Responsibilities for Hard Hats?

Assess Workplace For Hazards

As an employer, you must assess your workplace to determine if hazards are present that require the use of Hard Hats or other head protection. If such hazards are present, you must establish a complete safety protection program including selection, fit testing, training, maintenance and inspection.

Cut resisant glove ratings and explaination

Officially as of November 2016 a new version of the EN388 Mechanical Hazard standard has been in play and initially can be a little confusing.

The major change to the standard is the cut test. The reason for the change is that the old standard was no longer deemed fit for purpose because of improving technology.

The old standard (EN388:3002) uses the cut rating 1 – 5. The new standard (EN388:2016) still uses 1 – 5 but this has been amended compared to 2003 plus 2016 includes a secondary test rated A – F.

Most people in the Health and Safety/PPE world could easily get their head around the idea of 1 – 5 with 5 being the highest. Some manufacturers even adopted the traffic light system to make selection even more straight forward. I’ll leave our opinions on the Traffic Light system for conversation over a cup of tea

Gloves giving protection from mechanical risks

Protection against mechanical hazards is expressed by a pictogram followed by four numbers (performance levels), each representing test performance against a specific hazard.

|

|

1 Resistance to abrasionBased on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove. See table below. 2 Blade cut resistanceBased on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 4. 3 Tear resistanceBased on the amount of force required to tear the sample. 4 Puncture resistanceBased on the amount of force required to pierce the sample with a standard sized point. The protection factor is then indicated on a scale from 1 to 4. Volume ResistivityThis indicates Volume resistivity, where a glove can reduce the risk of electrostatic discharge. (Pass or fail test). These pictograms only appear when the gloves have passed the relevant test. If some of the results are markt with a X means that this test performance is not tested. If some of the results are markt with a O means that the glove did not pass the test. |

||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||

CUT RESISTANT GLOVES UPDATE JAN 2022

You may or may not know but cut resistant gloves standards were harmonised using a numbered level system, cut level 1,2 3 4 or 5.

They are/have been changed now to show cut levels A, B, C, D, E, F, and the way gloves are tested for cut resistance has changed too. It is down to changes made to the European Test for Mechanical Handling EN388:2003 .

Without boring you with science that you can easily find by searching on the internet, one of the reasons for the standards change was that glove materials were getting better at resisting cuts and during testing some were even blunting the testing blades, so a new way of testing was required. This testing was introduced and is called the TDM ISO cut test , EN 388:2016/ISO 13997.

If you are or were still buying older style cut level 3 or cut level 5 gloves there is no need to change....these are still good and can be purchased and used as designed, it's just that now there is another "level" beyond the old scope and is level F, the highest you can get. We will see glove manufacturers gradually adopting the new standards into the stream as production gathers pace.

see our cut resistant gloves here

OLD method EN388:2003

NEW ISO Method